Many guests from leading enterprises in the national heavy machinery industry, key scientific research institutes and authoritative experts gathered together to discuss the high-quality development path of the heavy machinery industry and draw a new blueprint for the development of the industry.

Yu Hong (first from right), deputy secretary of the party committee and vice president of Weihua Group, issued the certificate to the chief technician

During the exhibition, Yu Hong, deputy secretary of the Party Committee and Vice President of Weihua Group, was invited to attend the 2025 China Heavy Machinery Technology Conference and issued letters of appointment to the first batch of chief technicians in the heavy machinery industry. Weihua Group employees Han Yanhong, Liu Xinbo, and Wu Qingfu were awarded the titles of chief technician, young expert, and chief expert respectively.

As a grand event that comprehensively displays the latest development trends and innovative achievements of China's heavy machinery industry, Weihua Group appeared on the scene as an exhibitor, attracting many visitors. Weihua also gave its own answer to the hotly debated industry proposition of how to deal with the "high-end, intelligent, and green" industry proposition. Feng Jun, President of Henan Weihua, attended the conference and introduced the overview of Weihua to the guests.

Henan Weihua President Feng Jun (first from left) introduces the overview of Weihua to the guests at the exhibition

In response to the national "dual carbon" strategy and empowering enterprises to operate green and efficiently, Weihua relies on its years of technical accumulation in the lifting industry and its leading advantages in intelligent control technology to launch a new Chinese-style crane. Compared with traditional cranes, this product has span>The dead weight, height, and comprehensive energy consumption have been reduced by 15%-30%. Reconstructing the value of lifting products with green and low carbon empowers the high-quality development of the lifting machinery industry.

3800Large ton shipbuilding gantry machine

The 3800-ton super-large shipbuilding gantry crane on display this time is the world's highest grade and largest tonnage. It has reached the world's leading level in terms of equipment height, lifting height, lifting capacity, safety and reliability. It is another historic breakthrough in the field of heavy equipment.

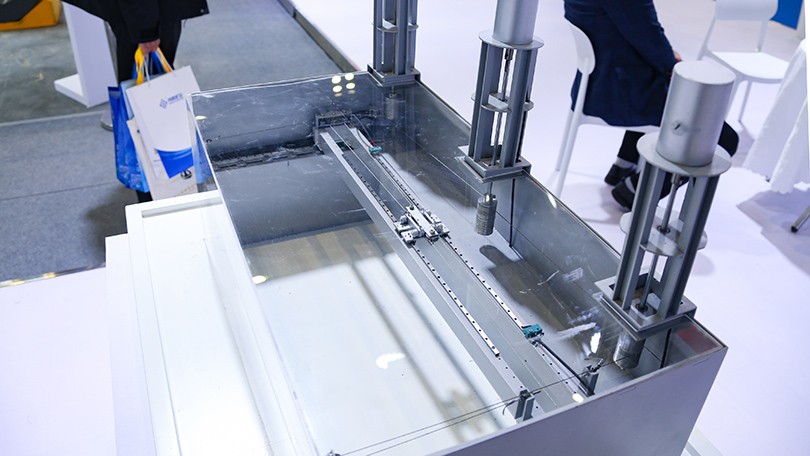

Truss Robot

Weihua's independently developed industrial crane bottom operationAICrane system, Turn lifting machinery into "hoisting robots", providing customers with intelligent control system integration and system solutions, reshaping the industry benchmark with intelligent operations, and providing better solutions for intelligent material handling.

500Ton four-beam six-rail cast bridge crane

Weihua's 500-ton four-beam and six-track metallurgical casting crane adopts ALMactive rectification feedback system and CMS monitoring system design, four-beam and six-track layout and main reducer inline structure, which makes the operation more stable and reliable, and the multi-mechanism redundant design ensures hoisting safety.

Nuclear Island gantry crane

Stainless Steel Hot Cell Crane

ExhibitedNuclear island gantry crane, is used for hoisting and transferring key equipment such as steam generators, reactor pressure vessels, and voltage regulators in nuclear power plants during the installation stage.

The stainless steel hot cell craneis installed in a high radiation environment and is divided into two parts: a hot room and a hot room. The product maintenance part has been successfully placed outside the hot room without radiation, protecting maintenance personnel from radiation damage.

The nuclear industry crane integrates Weihua's independently developed electrical anti-sway, remote control and other leading technologies to provide nuclear power companies with diversified lifting and material handling solutions, fully meeting customers' safety, reliability, energy saving, environmental protection, intelligent and efficient operational needs.

At present, Weihua has established a complete marketing management system and a professional technical service team in more than 30 provinces, cities and autonomous regions across the country, and has fully launched four major categories of business: installation, modification, maintenance and accessories. The "City Partner" program authorizes excellent service providers and incorporates them into Weihua's after-market service system, and actively explores the new "sales + service" model, to listen to users' needs and feedback more directly.

Whether it is "one-on-one VIP" exclusive user service, or "purchase, use, maintenance and care" full life cycle guarantee, we can provide convenient, efficient and considerate technical and service support with the latest solutions to meet users' needs for "efficiency, professionalism and quality".

In addition, as the first company in the global crane industry to apply 5G technology, Weihua uses big data centers to establish an industrial Internet platform to empower thecrane after-sales service market, Provide services such as remote operation and maintenance, remote monitoring, and remote fault early warning diagnosis, realize the full life cycle management of lifting equipment, and promote the transformation of Weihua Group from a production-oriented manufacturing enterprise to a service-oriented manufacturing enterprise.

Strength creates brilliance, and innovation leads the future. In the future, Weihua will continue to give full play to its innovation-driven and industrial integration advantages, build a solid core competitiveness in market competition, and contribute more "Weihua Power" to the high-quality development of the global machinery manufacturing industry.;.