A great power builds a super project with heavy equipment

Super project creates a better life

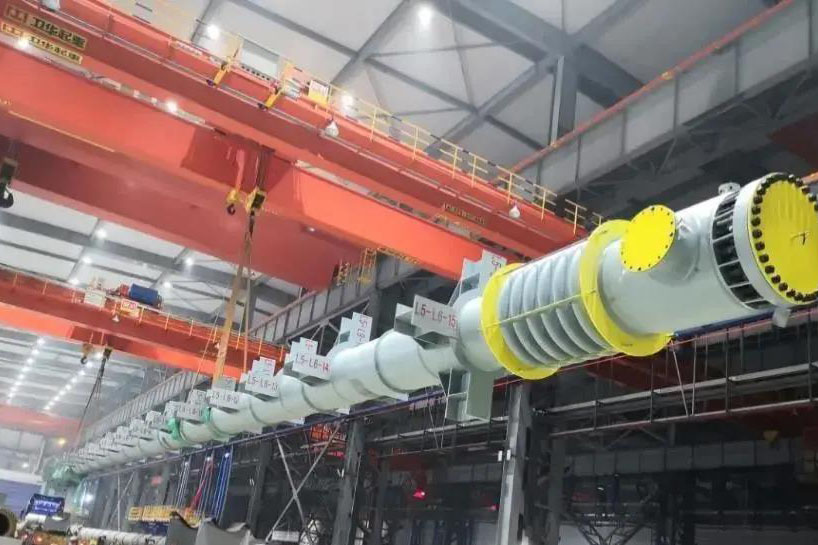

In mid-April this year, a loop reactor with an annual output of 1.2 million tons of copolymerized polypropylene was hoisted in Fuqing, Fujian. After the project is put into operation, it will change the situation of my country's large reliance on imported copolymerized polypropylene. The "big guy" in the video weighs 1,720 tons and consists of 16 55-meter-long and 8 180-degree large elbows. Previously, there was no device of the same scale at home and abroad. This is another breakthrough in the field of polypropylene devices by Tianhua Chemical Machinery and Automation Research and Design Institute Co., Ltd. (referred to as "Tianhua Institute"), a subsidiary of Sinochem, and another spark of Chinese wisdom. What does the production and manufacturing of heavy weapons in great countries rely on? Of course it is a powerful weapon for a great country! At the Nanjing production base of Tianhua Institute, Weihua's new Chinese-style bridge machine comes into play in the manufacturing process of the world's largest loop reactor. Multiple customized designs add more Chinese technology and Chinese strength to the manufacturing of heavy equipment in a big country!

What does the production and manufacturing of heavy weapons in great countries rely on? Of course it is a powerful weapon for a great country! At the Nanjing production base of Tianhua Institute, Weihua's new Chinese-style bridge machine comes into play in the manufacturing process of the world's largest loop reactor. Multiple customized designs add more Chinese technology and Chinese strength to the manufacturing of heavy equipment in a big country!  During the design stage of Tianhua Institute's Nanjing project, Weihua Technology Center conducted many technical exchanges with the customer, conducted in-depth research on the customer's actual production and manufacturing process, and took customer needs as the first design direction.Based on Weihua's new Chinese-style bridge crane, several customized-level designs for this project were successfully applied.

During the design stage of Tianhua Institute's Nanjing project, Weihua Technology Center conducted many technical exchanges with the customer, conducted in-depth research on the customer's actual production and manufacturing process, and took customer needs as the first design direction.Based on Weihua's new Chinese-style bridge crane, several customized-level designs for this project were successfully applied.  Mechanical design features ▶Using Weihua's new lightweight structural design, it has the characteristics of light weight, small wheel pressure, low vehicle height, low energy consumption, smooth operation without impact, and low noise. ▶All cranes use electronic weighing devices, and the weighing accuracy is less than 3‰, which solves the problem that electronic scale sensors of new structural cranes are difficult to install and the accuracy is difficult to control. ▶The lifting mechanism of the trolley adopts a statically determined force-bearing structure. The lifting and operation drive adopts a reducer, motor and brake to be integrated and fixed at three points. ▶Every lubrication system in the entire vehicle adopts electric centralized lubrication, and electric oil supply lubrication is performed regularly, saving labor costs and avoiding equipment oil pollution.

Mechanical design features ▶Using Weihua's new lightweight structural design, it has the characteristics of light weight, small wheel pressure, low vehicle height, low energy consumption, smooth operation without impact, and low noise. ▶All cranes use electronic weighing devices, and the weighing accuracy is less than 3‰, which solves the problem that electronic scale sensors of new structural cranes are difficult to install and the accuracy is difficult to control. ▶The lifting mechanism of the trolley adopts a statically determined force-bearing structure. The lifting and operation drive adopts a reducer, motor and brake to be integrated and fixed at three points. ▶Every lubrication system in the entire vehicle adopts electric centralized lubrication, and electric oil supply lubrication is performed regularly, saving labor costs and avoiding equipment oil pollution.  Electrical design features ▶Combined with Weihua’s independently developed anti-sway technology, it achieves joint lifting of multiple vehicles, precise control, and stable operation. ▶Using wireless communication technology to realize multi-vehicle linkage to meet the lifting solutions of different workpieces. ▶Use an absolute encoder for positioning, use laser ranging for linkage synchronization, and achieve precise control through program algorithms. ▶Adopt the integrated crane management system to realize functions such as fault information alarm, historical record query, and operation status analysis. In recent years, China's heavy machinery manufacturing level has made great progress. More and more important equipment of a great power are talked about by people, which has become the confidence of the Chinese people to be proud of. From "important equipment of a great country" to "important equipment of a powerful country", we still have a long way to go, and there will definitely be more Chinese companies with pursuits and dreams to move forward together. Weihua is fortunate to walk with you and make his own achievements and contributions to the realization of the dream of a powerful country!

Electrical design features ▶Combined with Weihua’s independently developed anti-sway technology, it achieves joint lifting of multiple vehicles, precise control, and stable operation. ▶Using wireless communication technology to realize multi-vehicle linkage to meet the lifting solutions of different workpieces. ▶Use an absolute encoder for positioning, use laser ranging for linkage synchronization, and achieve precise control through program algorithms. ▶Adopt the integrated crane management system to realize functions such as fault information alarm, historical record query, and operation status analysis. In recent years, China's heavy machinery manufacturing level has made great progress. More and more important equipment of a great power are talked about by people, which has become the confidence of the Chinese people to be proud of. From "important equipment of a great country" to "important equipment of a powerful country", we still have a long way to go, and there will definitely be more Chinese companies with pursuits and dreams to move forward together. Weihua is fortunate to walk with you and make his own achievements and contributions to the realization of the dream of a powerful country!