Product Name: Overhead Crane with Electromagnetic Beam

Span: 22.5-34.5m

Lifting Height: 15-16m

Working Duty: A6, A7

Overhead crane with electromagnet is a specialized product for lifting and moving steel products, steel plates and steel pipes. It is constituted by girder, traveling mechanisms, lifting trolley, electric parts and electromagnet spreader.

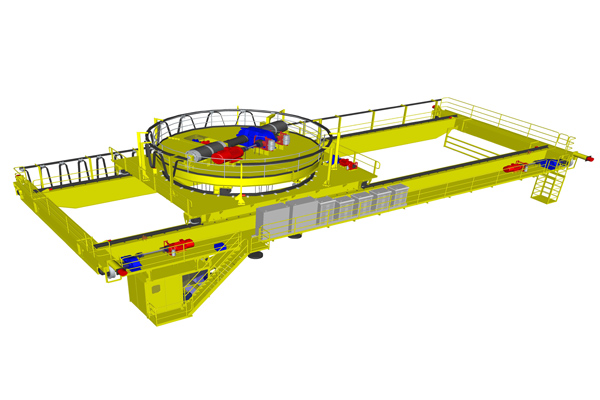

Overhead crane with electromagnetic beam is a specialized crane for lifting and moving steel products, steel plates and steel pipes. This crane is constituted by girder, traveling mechanisms, lifting trolley, electric parts and electromagnet spreader. The electromagnetic suction force of this overhead crane can last 10 minutes after power off. And the shape of electromagnet spreader could be customized bases on the shape of materials to be lifted, the magnet lifter can be round disc type megnetic lifter, square-type megnetic lifter, etc.

_(1).jpg)

There are 2 types of electromagnet spreader: electromagnetic chuck and electromagnetic beam. And electromagnetic beam can also be 2 kinds: non-rotating beam (vertical or parallel to main girder) and rotating beam (Upper beam or hanging beam).

Features of Overhead Crane with Electromagnatic Beam:

1. Three kind entrances to the cab: end, side and top entrances;

2. The rotating part of hook must be locked by screws during electromagnetic plate working;

3. Its lifting capacity includes the weight of electromagnetic part, and the weight of whole crane does not include the weight of electromagnetic chuck and its components;

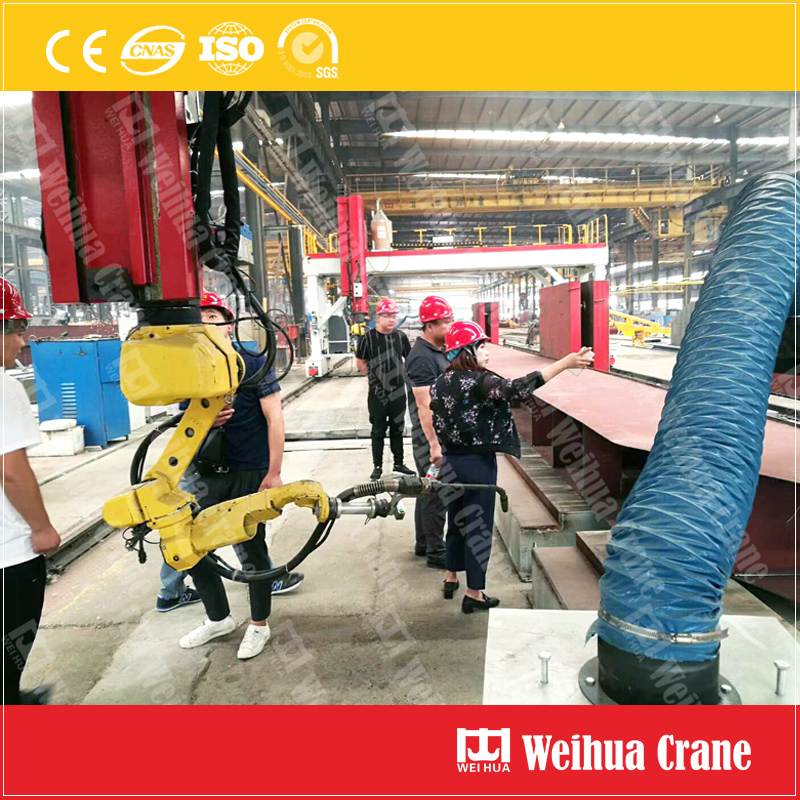

4. Box-typed girder structure is welded in high strength by robots;

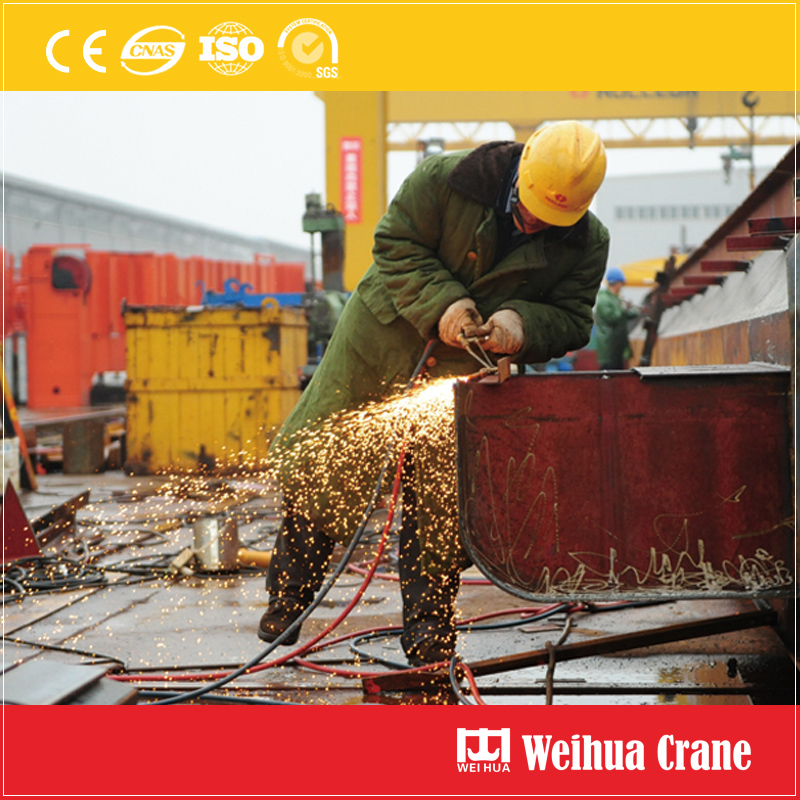

5. Wheels, wire rope winding drums, gears and couplings are manufactured by CNC with best quality;

6. Heavy-duty slip ring motor from Wuxi NGP, the best quality in China;

7. Electric equipment from German Siemens

8. Independent control system: wireless control or cab control;

9. Lifting overload protection device;

10. Polyurethane buffer;

11. Crane travel limit switch;

12. Decompression protection;

13. Emergency shutdown device;

14. Current overload protector;

.jpg)

.jpg)

Overhead Crane with Floodgate Lifting Beam on Dam Top

Overhead Crane with Rotary Electromagnetic Handling Beam For Steel Bar Handling

.jpg)

|

Capacity |

t |

7.5+7.5 |

10+10 |

16+16 |

17.5+17.5 |

|

Span |

m |

28 |

28 |

28 |

28 |

|

Work duty |

A7 |

A7 |

A7 |

A7 |

|

|

Max. lift height |

m |

12 |

16 |

16 |

16 |

|

Lift speed |

m/min |

12.9 |

11.9 |

12 |

12 |

|

Trolley speed |

m/min |

42.7 |

38 |

37.9 |

39.8 |

|

Crane speed |

m/min |

100 |

91.3 |

114 |

114 |

|

Hoisting motor power |

KW |

YZR280M-10/55 |

YZR315M-10/63 |

YZR355M-10/90 |

YZR355M-10/90 |

|

Trolley traveling power |

KW |

YZR200L-8/2×15 |

YZR160M2 |

YZR160L-6/11 |

YZR160L-6/11 |

|

Crane traveling power |

KW |

YZR200L-8/2×15 |

YZR180L-82×15 |

YZR225M-8/22×2 |

YZRM-8/22×2 |

|

Magnet weight |

kg |

|

|

|

|

|

Trolley weight |

kg |

14280 |

14980 |

16.23 |

16.50 |

|

Crane weight |

kg |

54280 |

62865 |

89.5 |

100.6 |

|

Max. wheel load |

KN |

240 |

280 |

39.0 |

40.6 |

|

Rail recommended |

kg/m |

38.43 |

38.43 |

QU70 |

QU100 |

|

Power supply |

AC 3P |

380v 500Hz |

380v 50Hz |

380v 50Hz |

380 50Hz |

| Lifting Capacity | Span |

Lifting Height |

Work Duty |

Lifting Speed |

Crane Traveling Speed |

Trolley Traveling Speed |

Total Power |

Track |

| t | m | m | m/min | m/min | m/min | KW | 43kg/m or QU70 | |

| 15 | 22.5~34.5 | 16 | A6 | 13.2 | 36.7 | 101.4 | 63 | |

| A7 | 15.8 | 36.6 | 103.9 | 79.5 | ||||

| 20 | 22.5~34.5 | 16 | A6 | 12.6 | 36.2 | 89 | 71 | |

| 15 | A7 | 15.8 | 42.8 | 103.9 | 94.5 | |||

| 32 | 22.5~34.5 | 15 | A6 | 12.5 | 37 | 87.3 | 111.3 | QU70 |

| 16 | A7 | 15.1 | 43.3 | 104.3 | 135.5 | QU80 | ||

| 40 | 22.5~34.5 | 16 | A6 | 11.7 | 37.5 | 87.3 | 128.5 | QU100 |

| A7 | 15.3 | 43.2 | 113.9 | 173 |