Product Name: Quayside Container Crane

Lifting Weight: 16t-55t

Above Rail: 18-24m

Outreach: 20-55m

This crane is a container handling gantry crane installed at large dockside for loading and unloading ship-borne containers from ships.

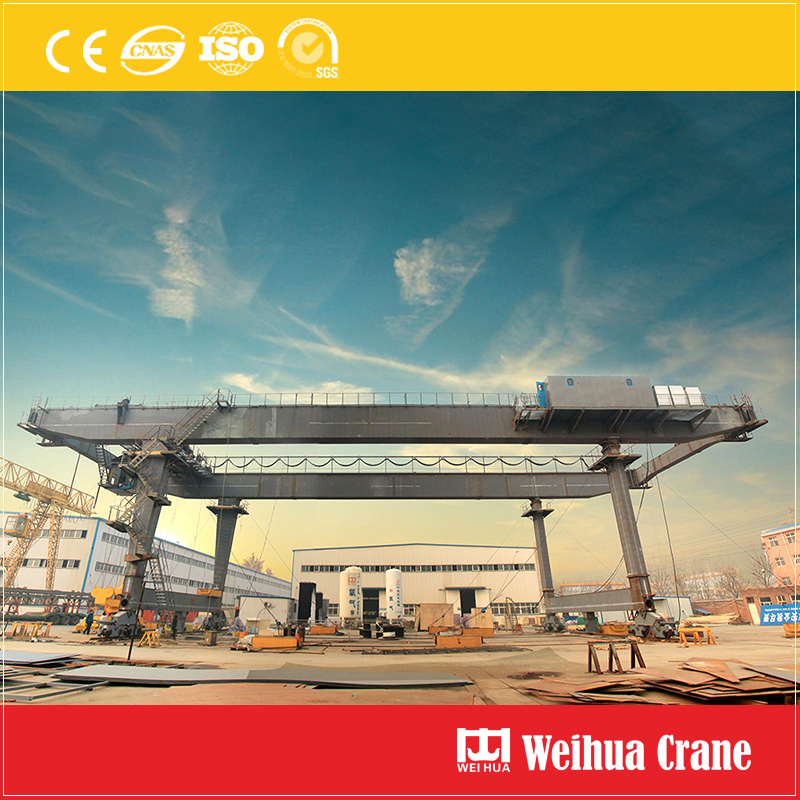

The quayside container crane is a container handling crane installed at large dockside for loading and unloading ship-borne containers to the container trucks. The dockside container crane is composed of a supporting frame that can travel on a rail track. Instead of a hook, the cranes are equipped with a specialized spreader which can be locked on the container.

1. Rated load lifting capacity (t/h ): 400, 500, 600, 800, 1000, 1250, 1500, 1800, 2000, 2250, 2500, 3000, 3600, 4000, 4500, 5000.

2. Rated load lifting capacity priority ( t ): 10, 12.5, 16, 20, 25, 32, 40, 45, 50, 56, 63, 71, 80, 90.

3. Working Level:

|

Standard |

GB3811-2008 |

|

Use Classes |

U8 |

|

Load-up Condition |

Q4 |

|

Work Level |

A8 |

4. Working Level of Mechanisms:

|

Mechanism |

Using Grade |

Load-up Condition |

Work Level |

|

Lifting/Closing |

T8 |

L4 |

M8 |

|

Trolley |

T8 |

L4 |

M8 |

|

Crane |

T5 |

L3 |

M6 |

|

Front Girder Pitching |

T4 |

L3 |

M5 |

|

Cab |

T4 |

L3 |

M5 |

5. Working Speed:

|

Mechanism |

Speed ( m/min ) |

|

Lifting/Closing ( full load/without load ) |

60~80/100~240 |

|

Trolley Traveling |

100~280 |

|

Crane Traveling |

20~40 |

|

Front Girder Pitching |

5~10 ( one way ) |

|

Cab Traveling |

20~25 |

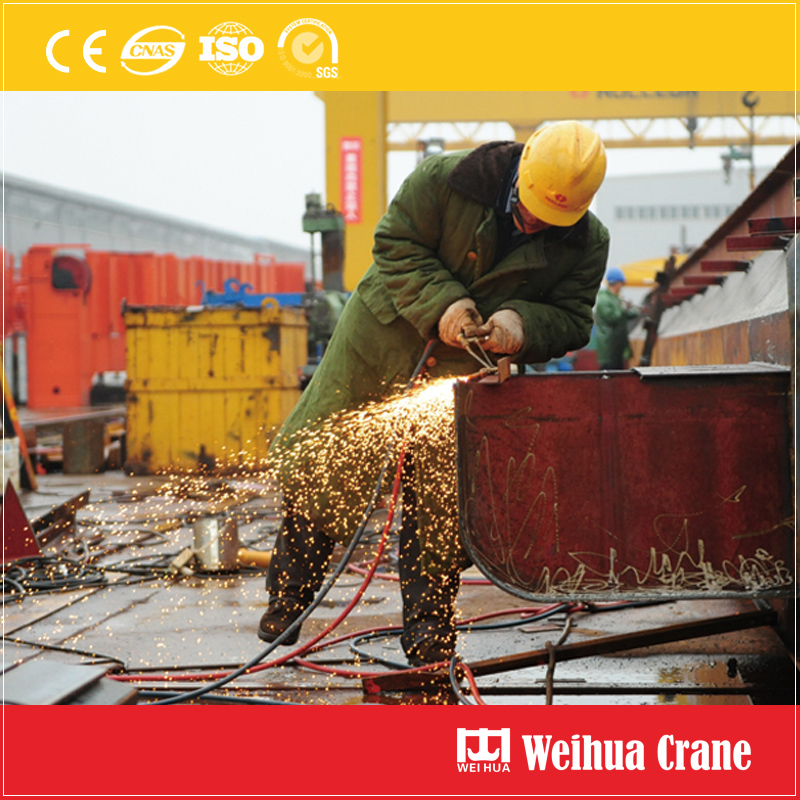

6. Steel Structure:

|

Design Service Time |

20~30 years |

|

Load Character |

Consecutive, heavy-duty, alternating |

|

Operating Character |

Cycle operation, work busy, high impact |

7. Components of Steel structure: crane chassis, back pull rod, tower frame, front pull rod, front girder, gantry frame, funnel scaffold, angling strut, back girder.

.jpg)

| Rated productivity priority | t/h | 600~2500 | ||

| Lifting Capacity | t | 16, 32 , 55 | ||

| Lifting Height | m | Above Rail 18~24 Below Rail 1 | ||

| Proportion of material stack | t/m³ | 0.9~3.0 | ||

| Max Outreach | m | 20~55 | ||

| Track Gauge | m | 17, 30 | ||

| Wheel Base | m | 12, 17 | ||

| Lifting/Closing Speed | m/min | 100~150 | ||

| Trolley Traveling Speed | m/min | 120~150 | ||

| Pitching Time | min | 5 | ||

| Crane Traveling Speed | m/min | 20 | ||

| Max Wheel Load | KN | 200 | ||

| Power Supply | 10KV, 50Hz, 3Phase | |||

Links: Rubber Tyred Gantry Crane | Rail Mounted Gantry Crane | Derrick Crane