Product Name: Wall Rail Jib Cane

Model: BB

Features: Running along the rail or orbit fixed on the wall, unique structure, flexible, saving room.

Application: Assembly workshop, production line, etc.

Product Name: Wall Rail Jib Crane

Model: BB

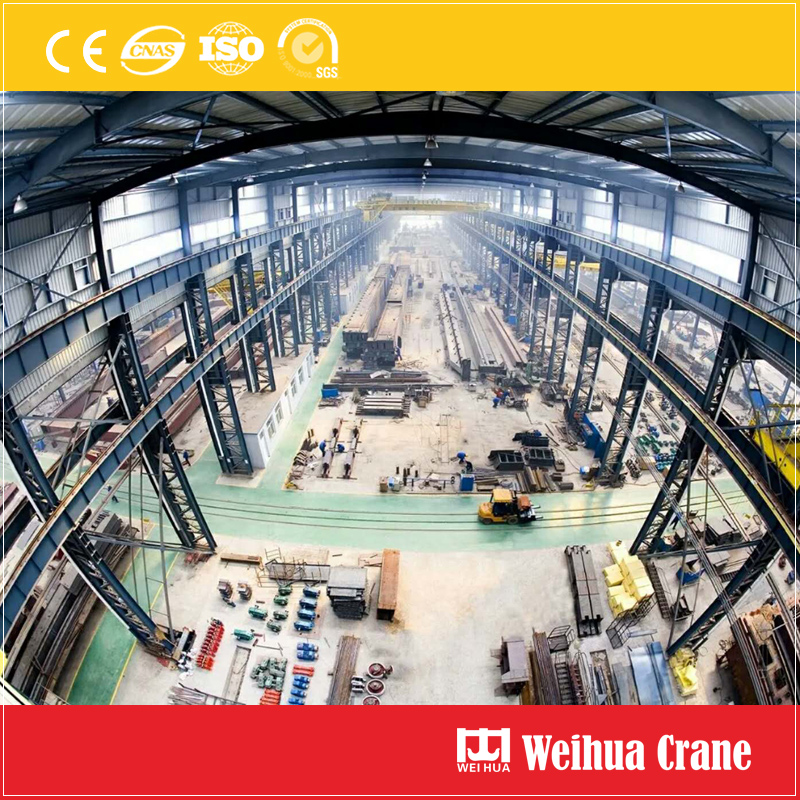

Brief Introduction: Wall rail jib crane is a special crane used in the workshop of machine manufacturing and assembling. It runs on the rail mounted on the wall in multilayer assembly shop. This jib crane can make the best of the space structure of the workshop, saving production place.

Features: Wall rail jib crane runs along the rail or orbit fixed on the wall, unique structure, flexible, saving room.

Application: Assembly workshop, production line, etc.

Introduction:

The wall-traveling jib crane is a jib crane that can run along an elevated track on a wall or other supporting structure. The rail track of the wall-traveling jib crane is installed on the concrete support column or steel support structural beam of the workshop/warehouse building. The jib crane can move longitudinally along the rail. At the same time, the electric hoist can do the horizontal movement along the jib arm/cantilever and the vertical hoisting task.

The wall-traveling jib crane greatly expands the working range, makes more effective use of the workshop space. It can be widely used in factories, mines, workshops, production lines, assembly lines and machine tools for loading and unloading, warehouses, docks and other sites for heavy lifting.

Wall-rail-traveling jib cranes are used in workshops or warehouses with large spans and large building heights. It is more suitable when lifting operations are frequent near the wall. Wall-rail jib cranes are mostly used in conjunction with overhead cranes above. Large workpiece/material are handled by bridge cranes. While wall jib cranes are designed for lifting light and small objects.

Specification:

1. Power: 3-phase AC; rated frequency: 50Hz; rated voltage: 380V

2. Working temperature: -20℃~+45℃; max related humidity is no less than 85%.

3. Work level: A3~A5.

Ordering Note:

The basic parameters (rated lifting weight, lifting height and arm length, etc.) of the wall rail jib crane shall be described clearly.

.jpg)

.jpg)

.jpg)

|

Capacity |

t |

10 |

|

Lifting Height |

M |

12 |

|

Duty |

|

A6 |

|

Speed |

m/min |

0.66/4.0 |

|

Traveling Speed |

m/min |

2.0~20 |

|

Fall |

|

4/1 |

|

Rail Width |

mm |

300-450 |

|

Max, Wheel Load |

kN |

34.9 |

|

Dead Weight |

Kg |

730 |

Links: Wire Rope Electric Hoist | Electric Chain Hoist | Flexible Suspension Crane