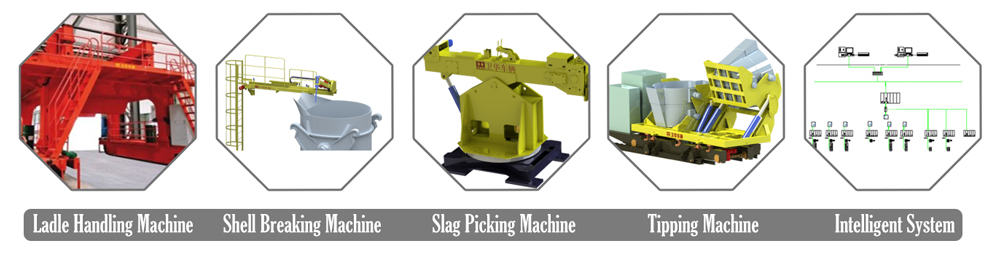

Product Name: Ladle Conveying Equipment

The ladle conveying equipment is used in metallurgical workshops for transporting ladle, adding molten metal to electric furnaces, centrifuges or molds.

Features:

1. The dumping process has small splashes, and the internal pollution of the workshop is easy to collect and handle.

2. The liquid exchange height is easy to control and the less heat loss.

3. Safety rigid support of ladles.

4. The molten liquid volume and flow rate are easy to control accurately, and the product quality is high.

5. Rigid walking mechanism, easy to control, good choice for auto digital factory.

The ladle conveying equipment is used in metallurgical workshops for transporting ladle, adding molten metal to electric furnaces, centrifuges or molds. This product adopts ground rail walking, direct flowing or dumping method to handle ladles. It is suitable for new cast production lines and old production line transformations, which is fully automated. The current station pouring is completed, and it automatically runs to the next station for pouring.

This machine is equipped with a ladle lifting and translation system to adapt to different ladle and casting molds.

Features:

1. The dumping process has small splashes, and the internal pollution of the workshop is easy to collect and handle.

2. The liquid exchange height is easy to control and the less heat loss.

3. Safety rigid support of ladles.

4. The molten liquid volume and flow rate are easy to control accurately, and the product quality is high.

5. Rigid walking mechanism, easy to control, good choice for auto digital factory.

6. High work efficiency and low cost.

Ladle handling machine with accurate weighing system and automatic positioning function

Core Technologies:

1. Upper floor with synchronous lifting;

2. Middle floor with synchronous traverse;

3. Intelligent pouring program for unattended operation

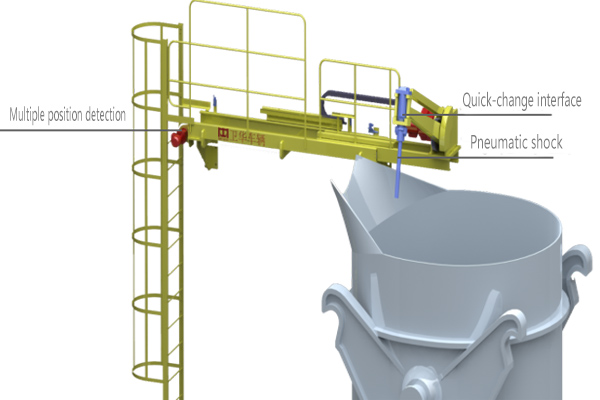

Molten metal scum shell breaking machine with precise positioning

Core Technologies:

1. Multiple security protections

2. Automatic detection and execution system

3. Pneumatic impact head uses the workshop air source to quickly break the surface dross in a specific area.

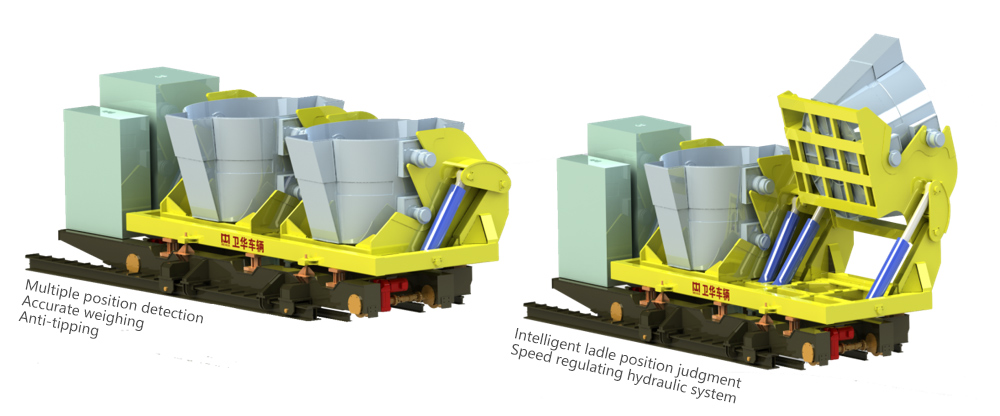

Double-ladle molten metal pouring machine

Core Technologies:

1. Precision weighing system;

2. Ladle position intelligent judgment system;

3. Ladle position anti-loosening design;

4. Precise positioning system;

5. One machine with 2-ladle space, saving space; redundant hydraulic system, high reliability.

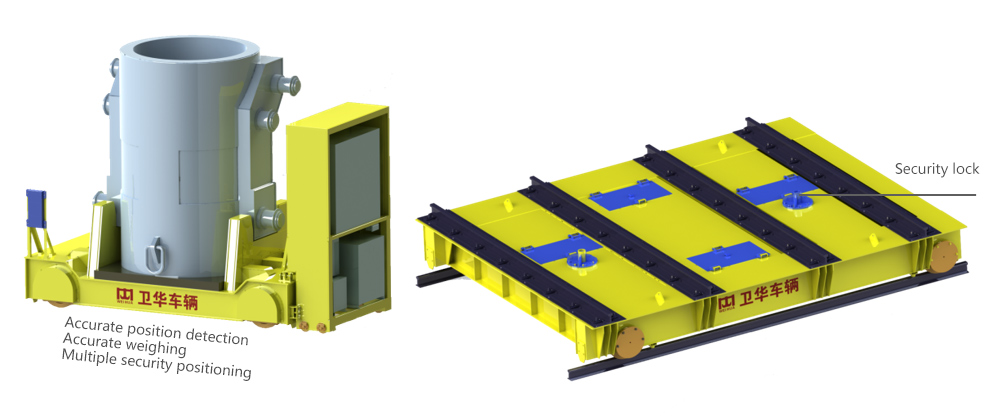

Molten metal transport and rail change system

Core Technologies:

1. Precision weighing system;

2. Precise positioning system;

3. Ladle position anti-loosening design;

4. The vehicles are locked to each other for high safety; the electric vehicle and the main vehicle have a six-degree-of-freedom buffer design to avoid vibration; the compact structure saves space; the overall wheel set is easy to replace.

Gray busbar high-precision positioning and mechanical limit double protection system

Core technologies

1. Real-time display of the position, accuracy ± 2mm

2. High temperature resistance

3. Strong anti-interference ability and stable performance

4. Multiple security protections

5. Flexible use of Gray bus, absolute encoder, travel limit, laser and other positioning combinations, high accuracy and reliability; omnidirectional antenna, leaky cable, optical fiber, industrial network cable and other signal transmission methods, covering a wide area, good signal.

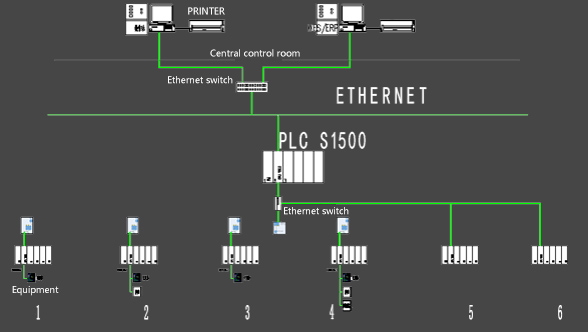

Automatic control technology of metallurgy industry production line with independent intellectual property rights

Core technologies

1. Hardware networking configuration;

2. Software program control;

3. On-site commissioning experience.