Working Load Limit (WLL): Ranges from 1 Ton to 100+ Tons (Custom capacities available)

Material: High-Yield Alloy Steel (Grade 100 / Grade 110)

Swivel Mechanism: Precision Ball or Roller Bearing Assembly

TAG: swivel crane hooks

Working Load Limit (WLL): Ranges from 1 Ton to 100+ Tons (Custom capacities available)

Material: High-Yield Alloy Steel (Grade 100 / Grade 110)

Swivel Mechanism: Precision Ball or Roller Bearing Assembly

This 320t overhead crane is the biggest metallurgical foundry crane ever made in Henan Province, China. Main structure of the 320t foundry crane is with 4 girders and 6 rails.

Read More >.jpg)

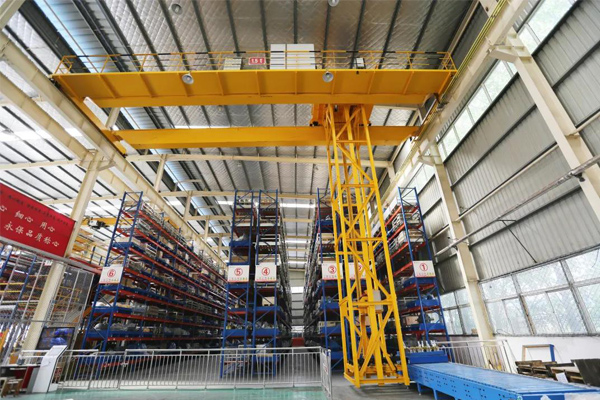

This intelligent steel pipe distribution overhead crane is used to distribute steel-pipes in production line before the steel-pipes being sawed. It can transport steel pipes from one roller table to any places intelligently.

Read More >.jpg)

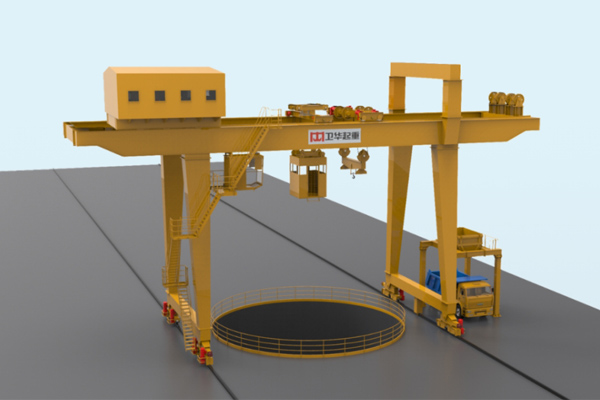

Rail-type container gantry crane is consists of the steel structure, lifting mechanism, micro-transfer mechanism, anti-sway system, travelling mechanism. Container Rail Mounted Gantry Crane can be used in inland terminals, container yard, rail freight station, coastal freight yard and frontier wharf.

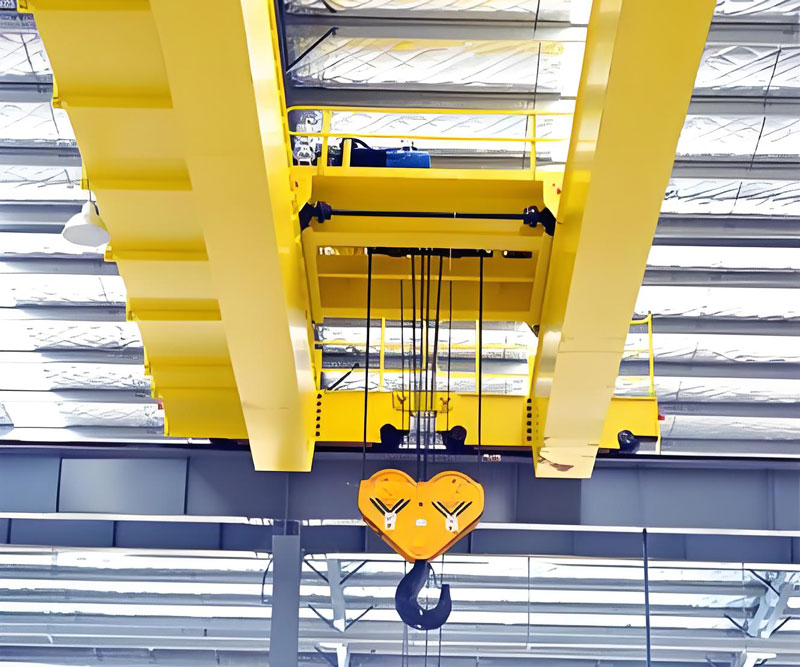

Read More >Our premium Swivel Crane Hooks are the critical link between your hoisting equipment and the load, designed to eliminate dangerous cable twisting and ensure perfect, controlled load alignment. Engineered for heavy-duty industrial applications, these hooks provide the ultimate combination of strength, durability, and safety, significantly reducing wear on your wire rope or chain and enhancing operational efficiency on any job site.

overhead swivel crane hooks

360° Free Rotation: The integrated, high-capacity swivel mechanism allows the hook to rotate freely under load. This prevents dangerous torque build-up in the wire rope or chain, which can lead to kinking, birdcaging, and premature failure.

Superior Load Control & Stability: By allowing the load to find its natural center of gravity, our swivel hooks minimize load spin and swing. This provides operators with greater control for precise positioning, especially when handling long, unbalanced, or delicate loads.

Enhanced Safety: Manufactured from high-grade, heat-treated alloy steel, each hook is built to exceed industry standards. The safety latch (where applicable) securely retains slings and attachments, and the robust design includes a high Safety Factor to protect your workforce and assets.

Reduced Equipment Wear: By absorbing rotational stress, the swivel crane hooks protects your more expensive hoisting equipment—including wire ropes, chains, and drums—from unnecessary wear and tear. This extends the service life of your entire rigging assembly and lowers long-term maintenance costs.

Heavy-Duty Construction: Featuring a precision-machined swivel bearing assembly with hardened races and balls/rollers, our hooks are built for smooth operation even under maximum load. The housing is forged for superior strength and impact resistance.

Versatile Applications: Ideal for a wide range of industries including construction, manufacturing, shipping, logistics, oil & gas, and mining. Compatible with overhead cranes, hoists, winches, and lifting slings.

Our swivel crane hooks are essential for any lifting task where rotation is a concern:

1. Lifting and turning pre-cast concrete panels

2. Handling long structural steel beams and pipes

3. Positioning machinery and equipment during installation

4. Marine and offshore lifting operations

5. Rotating loads for assembly or processing

6. Any application using multi-leg wire rope or chain slings

application

1. Rigorous Quality Assurance: Every single hook undergoes a thorough proof load test and is supplied with a full test certificate for traceability and peace of mind.

2. Engineered for Reliability: Our bearing design is optimized for smooth rotation under load, preventing seizing and ensuring long-term performance.

3. Global Compliance: Designed and manufactured to meet or exceed all major international safety and quality standards.

4. Expert Support: Our technical team is available to help you select the perfect hook for your specific application and load requirements.

To place an order or request a quote, please specify:

Required Working Load Limit (WLL)

Shank Type (e.g., Eye, Clevis, etc.)

Preferred Finish (Zinc Plated or Galvanized)

Latch Requirement (Yes/No and Type)

Invest in safety and performance. Upgrade your lifting operations with our industry-leading Swivel Crane Hooks.

Contact us today for a quotation and technical consultation.

Crane hook manufacturing process

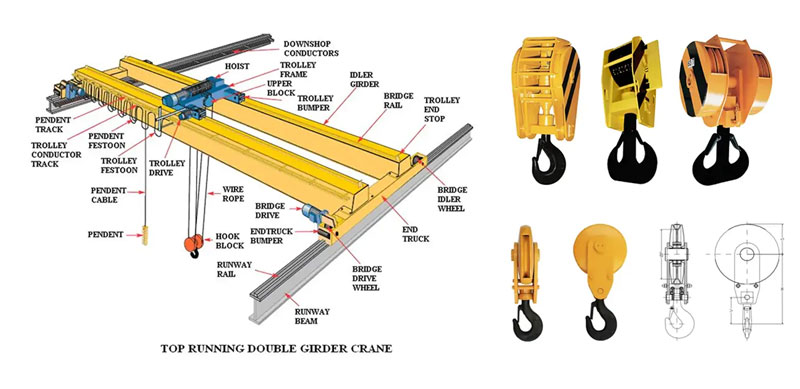

| Feature | Specification |

|---|---|

| Working Load Limit (WLL) | Ranges from 1 Ton to 100+ Tons (Custom capacities available) |

| Material | High-Yield Alloy Steel (Grade 100 / Grade 110) |

| Swivel Mechanism | Precision Ball or Roller Bearing Assembly |

| Finish | Electro-Zinc Plated (Standard), Hot-Dip Galvanized (for corrosion resistance) |

| Safety Latch | Certified Spring Latch or Bolt-Type Latch (Optional) |

| Design Standard | Complies with ASME B30.10, DIN 15400, and other international standards |

| Inspection & Testing | 100% Proof Load Tested and Certified |

Bridge Crane Hook

.jpg)

Overhead Crane Hook

Crane Hook

New Design Crane Hook

One-Stop Warehousing Logistics Solution

Weihua 2000t Gantry Crane for Offshore Wind Power Home Port

Gantry Crane with Lift Height 658m for Vertical Shaft Construction

Delivery of 320t Crane Reducer